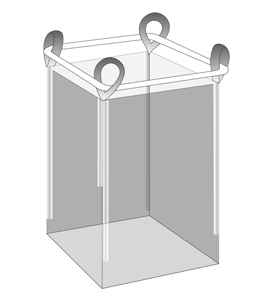

FIBC's / JUMBO BAGS

The FIBC bags are tailor made to fit the requirement of the individual customer ,its transportation and packed in material .These bags are typically used for packing variety of the products namely Food Grains , Agricultural Produce ,Chemicals , Animal Feed , Construction Material , Aggregates, Waste Collection etc. Today FIBCs are used in practically all the transportation and packaging needs were we have to move the bulk products with the minimum cost . These bags are invariably with UV stabilizer so that they last long under the ultra-violent sun rays .These bags are produced in 3 different styles U- Panel , Circular and the 4 +1 panel and with different filling and discharge options .

PIP is producing the FIBCs with following Features –

Bag Style – U-Panel , Circular , Baffle (Q-Bags), Single Loop bags and Double loop Bag

Fabric – 90 GSM to 275 GSM ,Coated & Uncoated , Type - A,B & C (Conductive ) ,Ventilated (Breathable )

Lifting Style – Cross Corner loops , Corner Loops , Stevedores Loops , Hood Loops, Side Tunnel Loops and Top Tunnel Loops , Single Loop & Double Loops

SWL – 500 lbs to 4500 lbs (200 kgs to 2000 kgs )

SF – 4:1 (Single Trip ) , 5:1 (Single Trip ) and 6:1 (Multi Trip )

Available Certifications – ISO 9001:2008 , ISO 22000:2005 (Food Grade) , Canadian Food Inspection Agency (Food Grade) ,UN Certification (UN Certified Bag) , Cotecna Inspection (Third Party Certification )

BRC (Food Grade ) (Coming up soon)

TOP FILLING OPTIONS

FIBCs are made with different top design according to the need of the filling method and machine.

FIBC top filling option are as under-

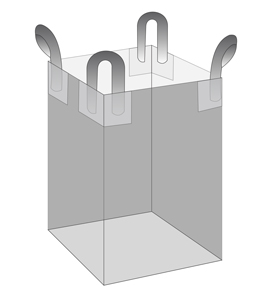

→ Open Top

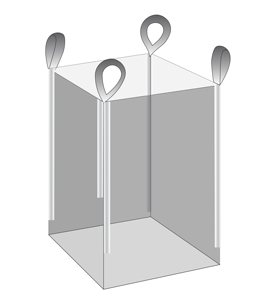

→ Duffle Top

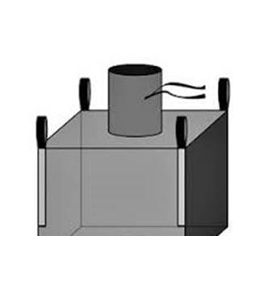

→ Filling Spout Top

→ Tie Down Flap Top

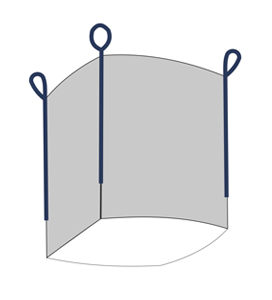

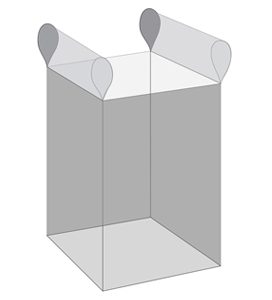

OPEN TOP

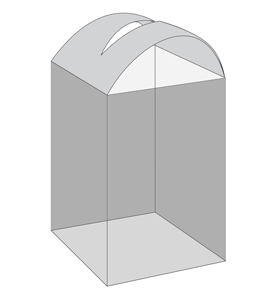

SKIRT TOP/DUFFEL TOP

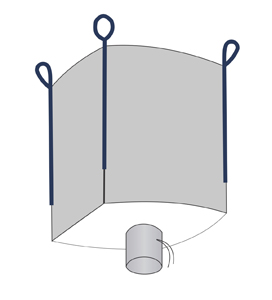

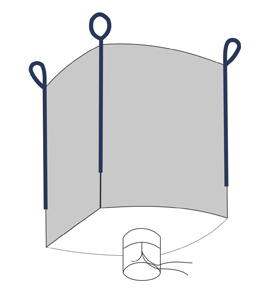

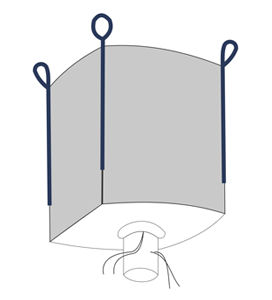

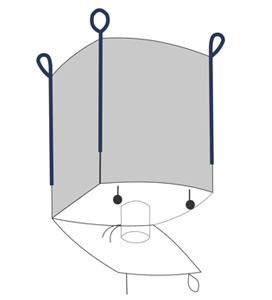

FILLING SPOUT

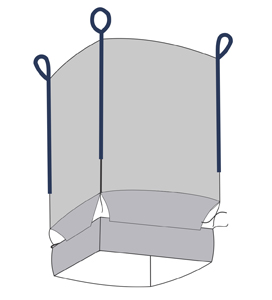

TIE DOWN FLAP TOP

BOTTOM DISCHARGE OPTIONS

PLAIN BOTTOM

DISCHARGE SPOUT

PAJAMA / DOUBLE SPOUT

STAR / PETAL SPOUT

SPOUT WITH FLAP

FULL OPEN BOTTOM

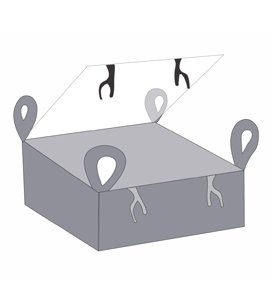

FIBC BAG ALSO COMES WITH THE DIFFERENT LIFTING OPTIONS

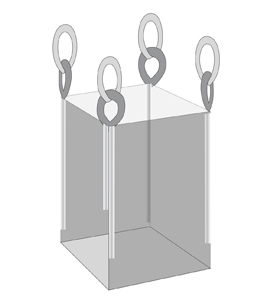

CROSS-CORNER LOOPS

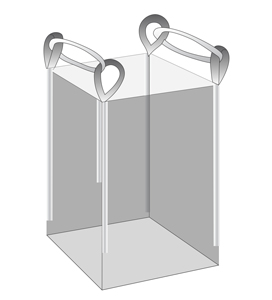

CORNER SEAM LOOPS

SLEEVE LIFT/ TUNNEL LIFT

HOOD LIFT

ANCILLARY LOOPS/ RING LOOPS

DOUBLE STEVEDORE STRAPS

SINGLE STEVEDORE STRAP

FINAL PRODUCTS